How do you know if your dredge is really automated?

Through the many years of automation consulting in the dredging industry, I often hear the phrase “my dredge is automated.” When I inquire as to what they actually have, I get responses such as, we have a production meter or we have DredgePack ™ on our dredge. Some even think that simply having a PLC (programmable logic controller) on the dredge somewhere constitutes dredge automation. These fallacies of automation stem from the lack of real world automation examples in this industry or its workforce as compared to advanced industries such as chemical or automotive.

Monitor and Control With Improved Efficiency

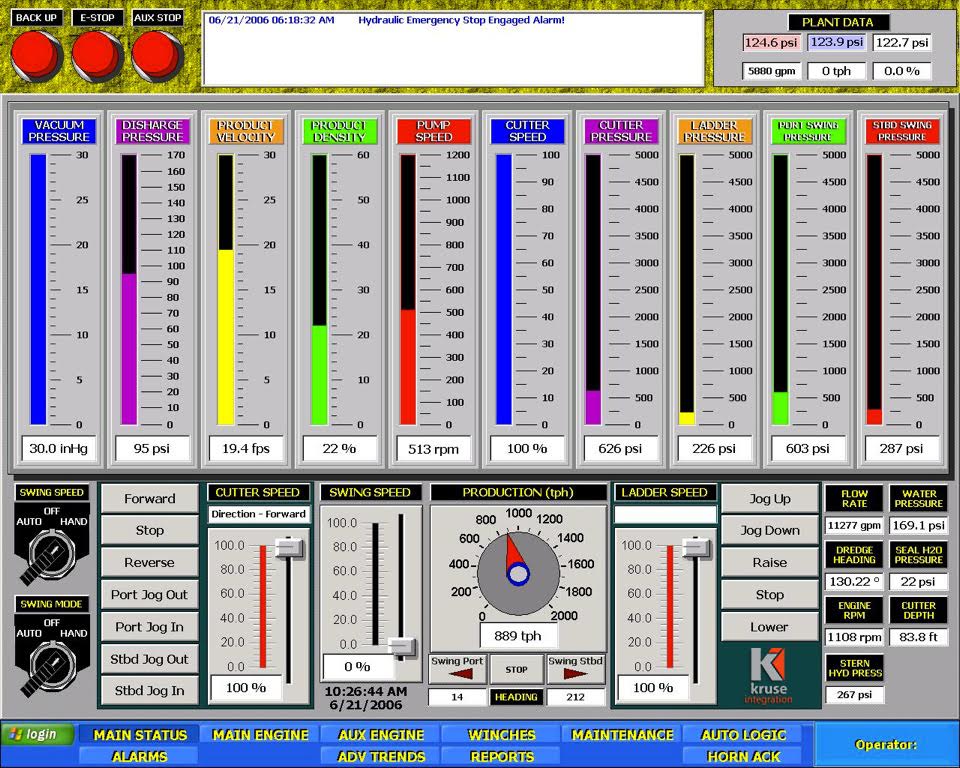

While it is true that automation can come in many forms throughout all industries, the typical automated system would actually monitor and control certain features with safety interlocks and improved efficiency over manual operation. A comple

tely automated dredge would have a PLC connected to all dredge system transmitters such as discharge pressure, suction pressure, product flow, product density, hydraulic levels, temperatures and pressures as well as engine parameters and GPS software.

The code in the PLC would have safety interlocks designed to keep the dredge operating within limits as well as interlocking equipment operation with necessary support devices as to validate that equipment can’t be operated without certain support devices operating. In addition, the code should include limit alarms, which would be annunciated on a graphical operator terminal along with many dredge parameter values and trends. The automation program in the PLC would have selectable automatic logic to allow features such as auto swing speed control based on vacuum, auto swing direction control based on distance from center cut line, profile contour control to keep the cutter within channel design, auto step advance control, product slurry concentration control or even automatic line plug detection and control based of flow algorithm.

Achieving Full Automation

In essence, a fully automated dredge would carefully monitor all parameters that an operator would typically be conscious of while keeping within design limits and peak operation. A fully automated dredge would also include a GPS (details covered in upcoming blogs) with positioning software and communication links to the PLC for many automated features that rely on GPS parameters.

Please visit www.KruseIntegration.com or contact me at jwise@kruseintegration.com. Feel free to forward this article to your coworkers whom you think would be interested.

Future blogs…

– GPS and positioning systems explained

– How to select a qualified system integrator

– Downtime and production database and reports

– Remote monitoring and remote booster pump control

– Budgetary reliable rugged mobile controllers for dredges in developing countries

– Dredge Instrumentation and justifications

– Dredge simulators

– Dredge contractors are thinking out of the box

– User friendly dredge controls and graphical interface